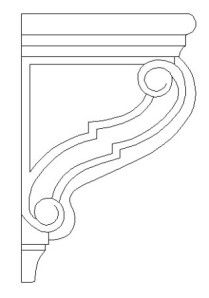

We made corbels today…these will provide support for the mantle in our earlier project. The dimensions for the 2 corbels are… 10 ¾” tall, 5 ½” wide with a depth of 8 ½”. The body of the corbels consist of 4 pieces…the 2 center pieces are 2” thick & the 2 outer pieces are ¾” thick. The 4 pieces will be machined individually…then we will glue them together. To complete the corbels, a cap & cove trim will be added to the body.

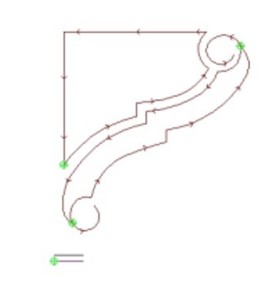

The cut files were produced in EnRoute Pro, our cad software program.

Detail on the 2 side panels required several machine processes. In summary, to avoid a long drawn out description, we ran a v-groove profile for line detail & used an end mill for the various recessed areas. These areas were machined to a ¼” depth from the surface height. Additional accent areas were machined using a 5/8” core box bit & a ½” radius bead bit.

After completing the detail, a ½” compression end mill was used for the offset cut.

We assembled our components with a generous amount of glue & Bessie clamps. We let the glue cure overnight to ensure a strong bond.

We completed this project by adding the cap and a 5/8” cove mold…

And that is how we did it!!!