Our customer has requested we make a radius crown molding for the ceiling of his yacht. The molding will be oval shaped…the dimensions are 60” on the long axis and 40” on the short axis…the profile of the crown will be 3” x 3”.

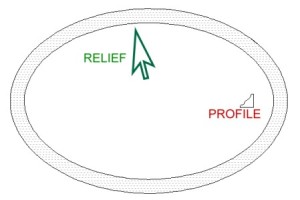

We began this project in our Cad program by creating the oval and the profile. We made the oval to specifications and offset to the inside 3” to allow for the molding width.

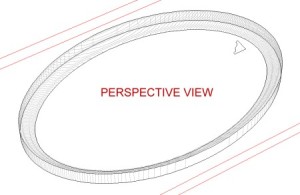

We made a flat relief and extruded the crown profile across the surface. The pictures that follow will give you a general idea of the process.

Since our molding will be painted, we started by cutting 3 oval shaped pieces of material from 1-1/8” mdf. Next we glued these together to give us the necessary height & width for our molding blank.

We will use 2 tool paths for this project because of the height. The first tool path will be a roughing pass utilizing a ½ end mill to remove the excess material. The second tool path will be our finished pass…we will use a ¼” ball nose bit to machine the profile.

We completed this project with a little sanding and a coat of primer.