We recently were asked to create a cornice molding to accent the balcony of a customers’ home. The project would require 80 linear feet …the profile measurements would be 15-7/8” in height and 3-¾” deep. This is not your typical molding by any stretch of the imagination. There aren’t any “ready made” profiles that fit the required size for this project, sooooo….

We decided to use a 9E casing profile as a starting point…this is a relatively common molding used for casing on doors & windows in most homes.

First we scanned a cross section of the 9E casing and imported the file into our Cad program. The standard width for most 9E casings is 3-1/4” with a thickness of ¾”. We enlarged the profile to the size we needed and with input from our customer, “tweaked” the new profile to his satisfaction!!!

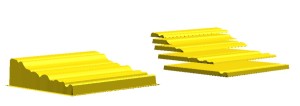

The new profile, because of the depth… 3-3/4”, would require a slicing technique. To do this, we created a flat relief…merged our profile and created 5 slices approximately ¾” thick.

We decided to make each section of molding 8 feet long to maximize the material we will be using. Each section will have the 5 slices of the profile we machine…these 5 slices were glued & stacked to create (1) 8’ section of molding…a total of 10 sections were needed!! We used approximately (12) 4’x8’ sheets of material for this project.

Pretty neat…